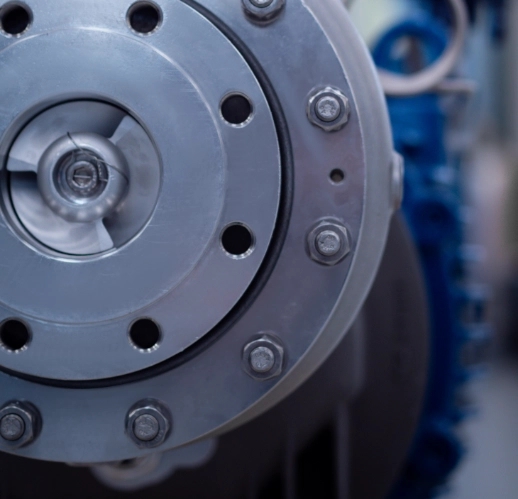

CRYOGENIC PUMPS FOR SMALL-SCALE LNG TERMINAL

![[object Object]](/_next/image?url=https%3A%2F%2Fcms.vanzettiengineering.com%2Fuploads%2F2_D_073d039561.png&w=1200&q=100)

MOBILITY

- Centrifugal pump on-board for LNG/Bio-LNG semi-trailers;

- Centrifugal pumps and skid for LNG/Bio-LNG transfer;

- L-CNG/Bio-LCNG refueling station pumps;

- Off-road applications LNG/Bio-LNG refueling system pumps;

- LNG/Bio-LNG receiving terminal pumps;

- Shore-to-Ship or Ship-to-Ship LNG/Bio-LNG bunkering pumps;

- Floating Storage Regassification Units (FSRU) cargo or booster pumps.

INDUSTRY

- Power generation LNG feed pumps;

- Satellite Plant or Peak shaving trailer unloading skid and booster pumps.

![[object Object]](/_next/image?url=https%3A%2F%2Fcms.vanzettiengineering.com%2Fuploads%2Fartika_series_182636e365.webp&w=1080&q=100)

![[object Object]](/_next/image?url=https%3A%2F%2Fcms.vanzettiengineering.com%2Fuploads%2Fesk_series_26_576e5100ea.webp&w=1080&q=100)

![[object Object]](/_next/image?url=https%3A%2F%2Fcms.vanzettiengineering.com%2Fuploads%2Fdsm_series_c3d0826630.webp&w=1080&q=100)

![[object Object]](/_next/image?url=https%3A%2F%2Fcms.vanzettiengineering.com%2Fuploads%2Fsgm_series_99ea1be513.webp&w=1080&q=100)

![[object Object]](/_next/image?url=https%3A%2F%2Fcms.vanzettiengineering.com%2Fuploads%2Fhgm_series_c09202ba47.webp&w=1080&q=100)

![[object Object]](/_next/image?url=https%3A%2F%2Fcms.vanzettiengineering.com%2Fuploads%2Fvt_1_70b020c1ae.webp&w=1080&q=100)

![[object Object]](/_next/image?url=https%3A%2F%2Fcms.vanzettiengineering.com%2Fuploads%2Fvt_3_series_90ca38bd06.webp&w=1080&q=100)

![[object Object]](/_next/image?url=https%3A%2F%2Fcms.vanzettiengineering.com%2Fuploads%2Fvt_100_series_37a18c1ecf.webp&w=1080&q=100)

![[object Object]](/_next/image?url=https%3A%2F%2Fcms.vanzettiengineering.com%2Fuploads%2Fhp_series_517083d6bb.webp&w=1080&q=100)

![[object Object]](/_next/image?url=https%3A%2F%2Fcms.vanzettiengineering.com%2Fuploads%2Fhph_series_c1acd32c3a.webp&w=1080&q=100)